Vibration analysis is an extremely powerful diagnostic and data trending tool to determine quantitative changes in machine health of rotating equipment. Read more…

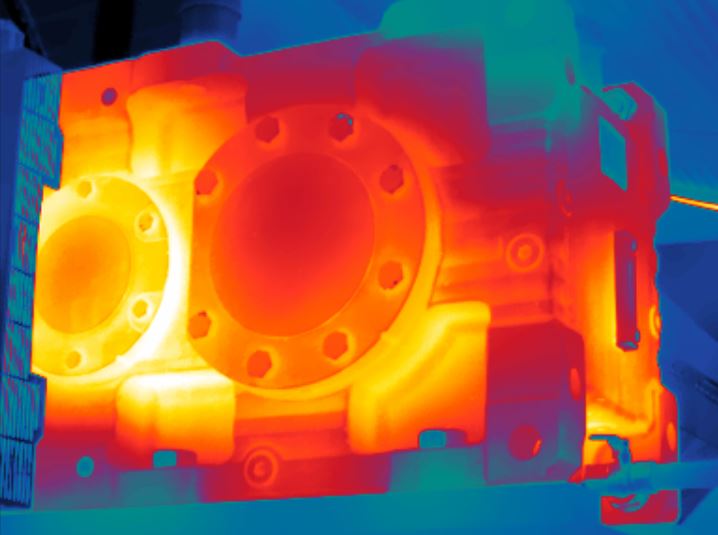

Infrared thermography has many industrial inspection applications such as electrical and mechanical inspection identifying component defects and machine performance… Read more…

Ultrasound is maybe the least familiar condition monitoring tool but the biggest payback for identifying early stage lubrication conditions that are root cause for machine failure. Read more…

Every rotating equipment reliability program needs a focus on lubrication best practices surrounding greasing PM’s, oil sampling and contamination control. Read more…

Monitor your balance-of-plant machinery by deploying wireless vibration sensors that seamlessly integrate with Acoem’s Nest i4.0 ecosystem. Read more…

Sometimes it’s not the machine but the foundation and structural integrity of the base under the machine causing repeat failures and maintenance turmoil. Read more…

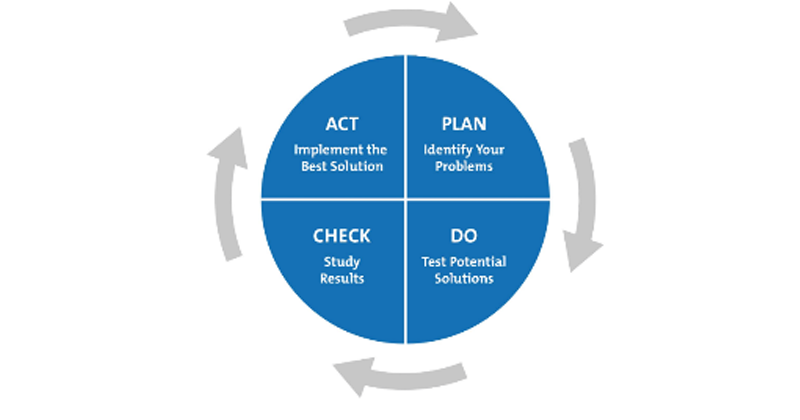

Implementing the Proactive Maintenance Model can be overwhelming at first as new inspection technologies and new culture transforms your maintenance strategy. Read more…